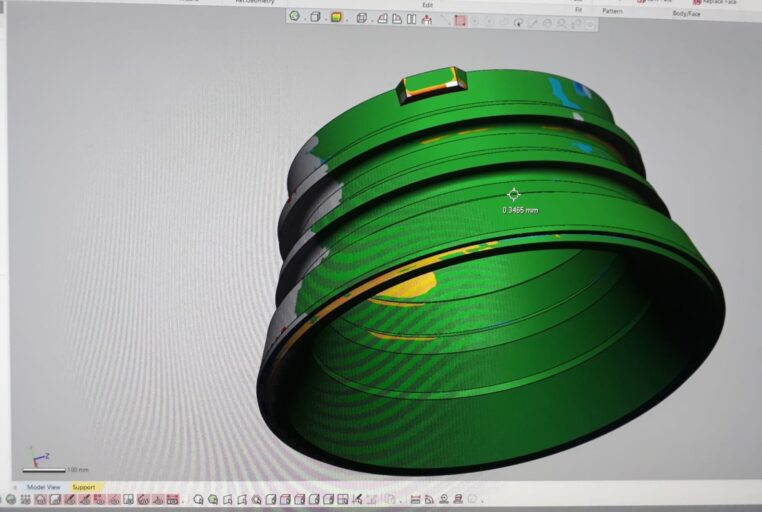

3D Scan reverse engineering can rapidly produce CAD models for prototype and legacy parts. At ValBrid we can receive the 3D scan data and can deliver it in any required CAD or graphic format. This CAD data can be used for inspection, mould design and pattern making, tool path creation, tooling verification or additive manufacturing and 3D printing.

Further to the generation of the CAD model, ValBrid can use the scan data and do an inspection against the original CAD model or perform analysis such as wear analysis.

3D scanning to reverse engineer an object is infinitely easier and more accurate than the use of traditional measurement methods such as callipers, something clients in high-risk industries such as aerospace, automotive, military, and medical areas place huge importance on.

Our team of engineers are specialists in working on point cloud data generated through 3D scanning equipment. With many years of experience working directly with OEM’s, various manufacturing processes and working within a range of industry sectors. Our engineers are on hand to discuss your projects requirements and offer advice on which method of reverse engineering best suits your needs. We have the knowledge to see your project right through from scan to manufacture.

We provide high-quality services in

IIFL Towers, 7th Floor, 143, Dr. MGR main road(off. OMR), Kandanchavadi, Perungudi, Chennai - 600096 India

+91 44-6680 5654 / +91 94990 12851

mail : sales@valbrid.com

© 2021, VALBRID. All Rights Reserved